This comprehensive guide details the process of installing cedar shakes, covering everything from preparation to finishing touches, ensuring a beautiful and durable roof.

Recent online resources showcase step-by-step instructions and videos, emphasizing proper techniques for a professional installation and long-lasting results.

Fastener selection is crucial, with stainless steel nails recommended for optimal corrosion resistance and secure attachment of the cedar shingles.

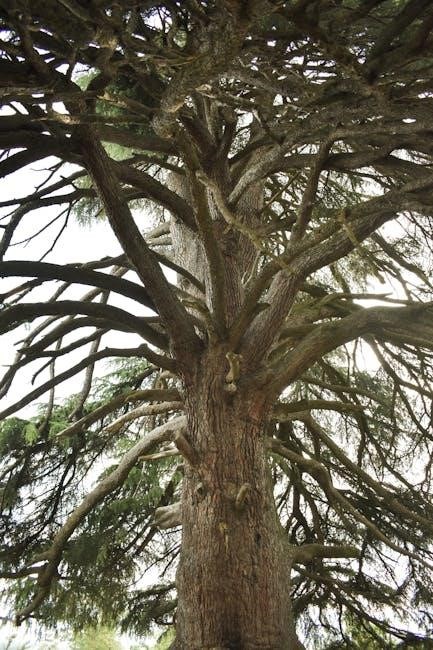

Cedar shake roofing offers a timeless aesthetic and natural durability, making it a popular choice for homeowners. This roofing system utilizes individual cedar wood shakes, hand-split or sawn, to create a textured and visually appealing roofline.

Historically valued for its weather resistance, cedar shake provides excellent insulation and longevity when properly installed. Modern installation guides emphasize the importance of correct fastening techniques and understanding shingle exposure based on roof pitch for optimal performance and a beautiful, lasting roof.

Tools and Materials Needed

Successful cedar shake installation requires a specific set of tools and materials. Essential supplies include cedar shakes, underlayment, roofing nails (preferably stainless steel), and a measuring tape.

Both hand and power tools are necessary, such as a hammer, utility knife, and potentially a pneumatic nailer for efficiency. Don’t forget safety gear – gloves, eye protection, and a sturdy ladder are paramount for a safe working environment.

Essential Hand Tools

For a quality cedar shake roof, several hand tools are indispensable. A sharp utility knife is crucial for precise cutting, while a chalk line ensures straight, consistent rows. A hammer, ideally with a magnetic nail holder, facilitates efficient fastening.

Measuring tapes and squares are vital for accurate layout and alignment. Don’t underestimate the importance of durable work gloves and safety glasses for protection throughout the installation process.

Power Tools for Efficiency

To expedite cedar shake installation, power tools are highly recommended. A pneumatic nailer or stapler significantly increases speed and reduces fatigue, ensuring consistent fastening. A circular saw, with a fine-tooth blade, allows for quick and accurate cuts of the shakes.

Consider a reciprocating saw for trimming around obstructions. Safety is paramount; always use appropriate hearing protection and follow manufacturer guidelines when operating power tools.

Cedar Shake Selection & Grading

Choosing quality cedar shakes is vital for a durable roof. Grades range from #1 (highest quality, fewest defects) to #3. Consider the climate; thicker shakes are better for harsh weather.

Inspect each bundle for splits, knots, and decay. Proper grading ensures consistent appearance and longevity. Prior to installation, assess the shingle’s humidity level for accurate spacing.

Roof Deck Preparation

A solid, dry deck is essential for cedar shake longevity. Thoroughly inspect the existing decking for rot, weakness, or damage. Repair or replace any compromised sections before proceeding.

Ensure the deck is clean and level, providing a uniform surface for underlayment. Proper preparation prevents premature shake deterioration and maintains structural integrity.

Inspecting the Existing Deck

Begin with a meticulous inspection of the roof decking, probing for soft spots or signs of water damage. Look closely at seams and areas around penetrations like vents.

Check for sagging or unevenness, indicating potential structural issues. Replace any rotted or weakened boards to create a stable foundation for the new cedar shake roof.

Repairing Damaged Decking

Address any compromised decking before proceeding with cedar shake installation. Carefully remove damaged sections, ensuring clean cuts to adjacent boards.

Replace with appropriately sized lumber, securely fastening it to the rafters. Prioritize structural integrity; a solid deck is paramount for a long-lasting, weatherproof roof. Ensure proper nailing patterns for maximum support.

Underlayment Installation – Importance & Types

Underlayment is critical for waterproofing, acting as a secondary defense against leaks. Choose between felt paper, synthetic underlayments, or rubberized asphalt options.

Overlap seams appropriately, typically six inches, and secure with staples or nails. Ensure complete coverage, paying close attention to eaves, valleys, and around roof penetrations. Proper installation prevents moisture damage.

Starter Course Installation

The starter course is foundational, ensuring proper alignment and preventing upward water migration. Use cedar shakes, installed upside down, to create a solid base.

Ensure a consistent overhang, typically one to two inches, and securely fasten each shake with appropriate nails or staples. This initial course dictates the quality of the entire roof.

Proper Alignment and Overhang

Achieving precise alignment is critical for a visually appealing and watertight cedar shake roof. Maintain a consistent overhang, generally between one and two inches, along the eaves and rakes.

Use a chalk line to establish a straight edge, ensuring each shake is uniformly positioned. This meticulous approach prevents uneven exposure and contributes to long-term durability.

Fastening the Starter Course

Securely fasten the starter course with two nails or staples per shake, ensuring they penetrate the underlying decking. Utilize 31mm x 1.8mm stainless steel ring shank nails for superior holding power.

Alternatively, the ShingleFix stapler offers a quicker installation method, but proper fastening remains paramount for preventing blow-off and maintaining roof integrity.

Installing the First Few Courses

Maintain consistent exposure as you install the initial courses, carefully aligning each shake to create a visually appealing and weather-tight roof. Staggering the joints is vital for structural strength and preventing water penetration.

Regularly check for proper alignment and ensure each shake is securely fastened, building a solid foundation for subsequent courses and long-term performance.

Maintaining Consistent Exposure

Accurate exposure is key; determine the correct amount based on your roof’s pitch, adjusting for humidity as cedar shakes naturally expand and contract. Consistent exposure ensures uniform aesthetics and optimal weather protection.

Carefully measure and align each course, using a story pole as a guide to maintain the desired reveal, preventing gaps and ensuring a professional, long-lasting cedar shake roof.

Staggering Joints for Strength

Strategic staggering of joints is vital for a robust roof structure. Avoid aligning vertical joints across multiple courses, creating a more interwoven and resilient roofing system.

This technique distributes stress, preventing concentrated weak points and enhancing the overall integrity of the cedar shake installation, contributing to its longevity and weather resistance.

Fastening Techniques

Secure fastening is paramount for a durable cedar shake roof. Options include nails or staples, with stainless steel being the preferred material to resist corrosion and ensure longevity.

Generally, double fastening – two nails or staples per shake – is recommended. Proper placement is key; drive fasteners straight and avoid overdriving, which can damage the wood.

Nail vs. Staple – Pros and Cons

Nails offer superior holding power and are traditionally favored for cedar shake roofing, providing a robust and lasting connection. However, they require more effort for installation.

Staples are faster to apply, especially with pneumatic tools, increasing efficiency. ShingleFix staples are specifically designed for this purpose, but may not offer the same long-term security as nails.

Correct Nail/Staple Placement

Cedar shakes should be twice fastened – either nailed or stapled – to ensure secure attachment and resistance to wind uplift. Proper placement is key; drive fasteners straight and at a slight downward angle.

Utilize a 31mm x 1.8mm stainless steel ring shank nail for optimal holding. Staples must fully penetrate the shake and decking, avoiding angled or incomplete penetrations that compromise integrity.

Fastener Corrosion Resistance (Stainless Steel)

Employing stainless steel fasteners is paramount for longevity, preventing rust and staining on your cedar shake roof. Traditional fasteners corrode, weakening the roof and potentially damaging the wood.

Stainless steel resists weathering, maintaining its strength and providing lasting security. Investing in quality stainless steel – like 316 grade – safeguards against corrosion, ensuring a durable and aesthetically pleasing roof for decades;

Exposure and Spacing

Proper exposure and spacing are critical for weather resistance and aesthetic appeal. Exposure refers to the visible portion of each shake, determined by roof pitch; steeper pitches require less exposure.

Consider humidity’s impact, as wood expands and contracts. Adjust spacing accordingly to prevent buckling or gaps. Accurate exposure ensures proper water runoff and prevents premature deterioration of the cedar shakes.

Determining Correct Exposure Based on Roof Pitch

Roof pitch significantly influences exposure; steeper slopes necessitate reduced exposure to prevent water penetration. Generally, lower pitches require greater exposure for effective runoff. Manufacturers provide charts correlating pitch to optimal exposure measurements.

Carefully measure your roof’s pitch and consult these guidelines. Incorrect exposure compromises the roof’s integrity, leading to leaks and premature aging of the cedar shakes.

Adjusting for Humidity – Shingle Movement

Cedar shakes naturally expand and contract with humidity changes. Account for this movement during installation to avoid buckling or fastener issues. Prior to installation, assess the shingle’s current moisture content.

Slightly looser fastening allows for expansion, while overly tight fastening can cause cracking. Adjust exposure accordingly, recognizing that shakes will swell in humid conditions.

Working Around Roof Obstructions

Chimneys, vents, and skylights require careful flashing details to maintain a waterproof seal when installing cedar shakes. Cut shakes precisely to fit around these obstructions, ensuring proper overlap with adjacent courses.

Utilize appropriate flashing materials – metal or specialized roofing underlayment – to prevent water intrusion. Pay close attention to detailing around penetrations for long-term protection.

Chimneys, Vents, and Skylights

Successfully navigating these roof features demands precision. Proper flashing is paramount, creating a watertight barrier where these elements meet the cedar shake roofing system. Detailed metalwork, specifically step flashing integrated with the shakes, is essential.

Carefully cut shakes to conform to the shapes of vents and skylights, maintaining consistent exposure. Ensure adequate underlayment extends up the chimney or skylight base for added protection.

Flashing Details for Waterproofing

Effective flashing is the cornerstone of a leak-proof cedar shake roof. Step flashing, integrated with the shakes, directs water away from vulnerable areas like chimneys and walls. Valley flashing requires precise weaving or stepping of shakes to channel water effectively.

Utilize high-quality metal flashing – copper, aluminum, or galvanized steel – ensuring compatibility with cedar. Proper overlap and sealing of flashing components are critical for long-term waterproofing performance.

Ridge Cap Installation

Ridge caps protect the peak of your roof, demanding precise cutting and fitting for a weather-tight seal. Overlap ridge caps adequately, typically with a minimum of six inches, and ensure consistent exposure. Securely fasten each cap using corrosion-resistant nails, spacing them appropriately for optimal hold.

Proper alignment is key, creating a visually appealing and functionally sound ridge. Consider the roof pitch when determining the necessary cap length and angle for a perfect fit.

Cutting and Fitting Ridge Caps

Accurate cuts are essential for a clean, professional ridge cap installation. Begin by measuring the ridge length and accounting for necessary overlaps. Use a circular saw or hand saw to carefully cut the caps, ensuring clean, straight edges. Dry-fit each cap before fastening, adjusting as needed for a snug, even alignment.

Consider the roof’s pitch when angling the cuts, creating a seamless transition along the ridge line. Precise fitting minimizes gaps and maximizes weather protection.

Securely Fastening Ridge Caps

Proper fastening is critical for ridge cap durability. Utilize corrosion-resistant nails – stainless steel is highly recommended – to prevent future issues. Nail through the ridge cap into the underlying cedar shakes, ensuring adequate penetration. Space nails evenly, typically every 12-16 inches, for optimal holding power.

Avoid overdriving nails, which can split the wood. A consistent, secure fastening pattern guarantees a weather-tight and long-lasting ridge cap installation.

Valley Installation

Valley installation demands meticulous flashing to prevent leaks. Proper flashing, installed underneath the cedar shakes, directs water away from the roof’s vulnerable areas. Techniques include weaving or stepping the shakes, creating an interwoven pattern for enhanced protection.

Ensure adequate overlap and secure fastening of the shakes within the valley. A correctly installed valley is essential for a watertight and durable cedar shake roof.

Proper Valley Flashing Techniques

Effective valley flashing is paramount for preventing water intrusion. Begin with a metal valley flashing, extending at least 6 inches up each roof slope, covered by an underlayment layer. This creates a waterproof base.

Carefully overlap flashing sections, ensuring a shingle-tight fit. Proper sealing of seams with roofing cement is vital. Prioritize a robust, multi-layered approach for lasting protection against the elements.

Weaving or Stepping Cedar Shakes in Valleys

Two primary methods exist for valley coverage: weaving and stepping. Weaving involves alternating full shakes on each side, creating an interwoven pattern for enhanced water resistance. Stepping utilizes full shakes on one side, trimmed to half-width on the other.

Regardless of the method, maintain consistent exposure and secure each shake with appropriate fasteners. Precise cutting and careful alignment are crucial for a visually appealing and watertight valley.

Finishing Touches and Trim

Completing the roof requires careful attention to detail. Install drip edge along the eaves and rakes to direct water away from the fascia. Consider the fascia and soffit, ensuring proper ventilation and a clean aesthetic.

These final elements protect the underlying structure and contribute to the overall longevity and appearance of your cedar shake roof, enhancing its weather resistance.

Drip Edge Installation

Proper drip edge installation is vital for diverting water away from the fascia and protecting the underlying roof structure. It should be installed along the eaves and rakes, extending beyond the drip line.

Ensure a secure attachment using corrosion-resistant fasteners, overlapping seams correctly to prevent water penetration. This crucial step safeguards against wood rot and maintains roof integrity.

Fascia and Soffit Considerations

Inspect fascia boards for rot or damage before installing cedar shakes, repairing or replacing as needed to provide a solid mounting surface. Proper ventilation is key; ensure soffits allow adequate airflow to prevent moisture buildup.

Consider the material of your fascia and soffit, choosing options compatible with cedar and resistant to the elements for long-term durability and aesthetic appeal.

Cedar Shake Maintenance

Regular cleaning is vital to remove debris, moss, and algae, preserving the wood’s natural beauty and extending its lifespan. Periodic inspections help identify potential issues like cracked or missing shakes early on.

Consider applying a wood preservative or stain to protect against UV damage and moisture, maintaining the cedar shake’s integrity and color for years to come.

Cleaning and Preserving the Wood

Gentle cleaning with a soft brush and water removes dirt and debris without damaging the cedar. Avoid high-pressure washing, which can erode the wood fibers. Applying a wood preservative or stain offers UV protection.

Regular treatments prevent cracking and warping, maintaining the shake’s aesthetic appeal and structural integrity. Choose products specifically designed for cedar to ensure compatibility and effectiveness.

Identifying and Addressing Potential Issues

Regular inspections reveal early signs of decay, splitting, or missing shakes. Address these promptly to prevent extensive damage. Look for moss or algae growth, indicating moisture retention.

Replace damaged shakes immediately, ensuring a proper fit and secure fastening. Investigate the cause of any issues – poor ventilation or inadequate flashing – and correct them to avoid recurrence.

Common Installation Errors to Avoid

Incorrect nail placement is a frequent mistake, leading to reduced holding power and potential leaks. Insufficient exposure or inconsistent staggering of joints compromises weather protection.

Skipping underlayment or improper flashing around chimneys and vents are critical errors. Using improper fasteners, like non-corrosion resistant staples, shortens roof lifespan. Always follow manufacturer guidelines!

Building Codes and Regulations

Local building codes significantly impact cedar shake installations, often dictating fire resistance requirements and acceptable fastening methods. Permits are typically required before commencing work, ensuring compliance with safety standards.

Regulations may specify underlayment types, shingle grading, and proper flashing details. Ignoring these codes can result in failed inspections and costly rework – always verify local rules!

Cost Considerations for Cedar Shake Roofing

Cedar shake roofing represents a premium investment, with material costs generally higher than asphalt shingles; Installation labor also contributes significantly to the overall expense, due to the skill required for proper application.

Factors like roof complexity, pitch, and accessibility influence pricing. While initially more expensive, cedar shake offers longevity and aesthetic appeal, potentially offsetting costs over time.

Resources and Further Information

Explore the National Rail network portal for UK train travel information, including schedules and fares, aiding logistical planning for material sourcing. Bravas provides detailed installation guides based on industry best practices and reliable expertise.

TrainTickets.com offers real-time updates for efficient journey planning. Avanti West Coast’s website features a handy train times tool, supporting project coordination and material delivery.