DVC6200 Instruction Manual: Overview and Key Features

This manual details connecting the fieldbus to the DVC6200, covering manual setup options, actuator adjustments, and hazardous area compliance information․

The Fisher FIELDVUE DVC6200 series represents a significant advancement in digital valve control technology․ This instruction manual provides comprehensive guidance for installation, configuration, and maintenance of these controllers․ Designed for use with GX control valves, the DVC6200 offers precise control and enhanced diagnostic capabilities․

Understanding the principles of FOUNDATION Fieldbus is crucial for successful integration, with resources available from the Fieldbus Foundation․ Proper alignment during mounting, specifically vertically aligning the magnet assembly, is essential for optimal performance․ The DVC6200 allows for both default factory configurations and customized manual setups to meet specific application needs․

DVC6200 Series Variations (HW1, HW2, SIS)

The FIELDVUE DVC6200 series encompasses several hardware revisions – HW1, HW2, and SIS – each tailored for specific applications and safety requirements․ The HW1 version represents the initial release, while HW2 incorporates enhancements and updated features․ Crucially, the DVC6200 SIS variant is specifically designed for Safety Instrumented Systems (SIS), adhering to stringent safety standards․

Referencing the appropriate instruction manual, such as D103412X012 for the DVC6200f, is vital as features and configurations may differ between these models․ Nameplate information clearly indicates the specific hardware version and associated certifications, including hazardous area approvals․

Installation and Mounting

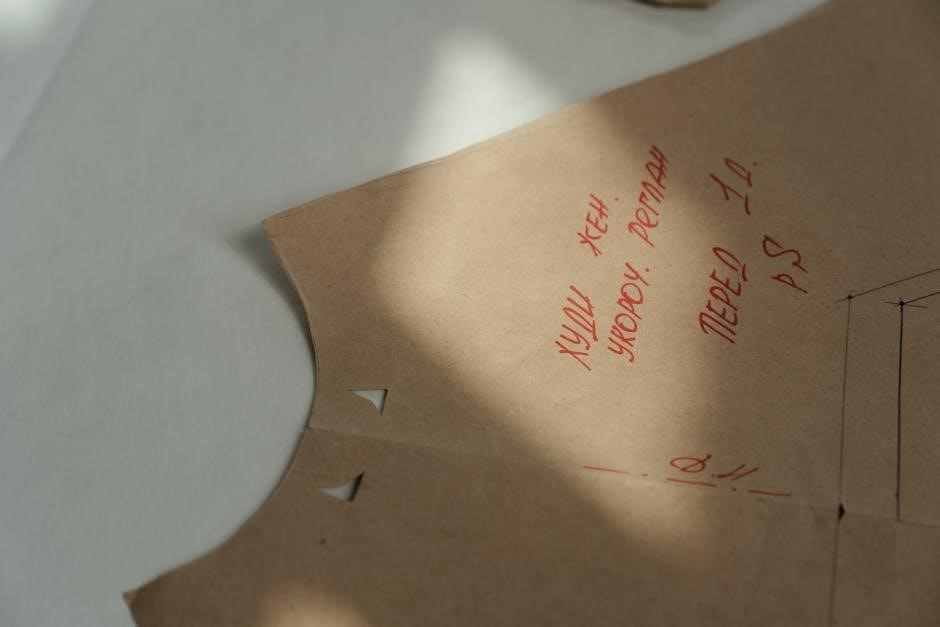

Proper alignment is key during installation; vertically align the magnet assembly, ensuring the centerline matches the valid travel range on the DVC6200․

Mounting Considerations and Alignment

Careful mounting and alignment are crucial for optimal DVC6200 performance․ Ensure a stable mounting surface capable of supporting the controller’s weight․ When aligning, vertically position the magnet assembly, meticulously lining up the centerline of the alignment template․ This alignment should closely correspond with the lower extreme of the valid travel range indicated on the magnet assembly itself․

Pay close attention to the index mark located on the pole pieces at the back of the DVC6200 housing․ Proper positioning of this mark is essential for accurate operation and reliable control․ Incorrect alignment can lead to performance issues and reduced lifespan, so double-check all adjustments․

Fieldbus Connection Procedures

This manual specifically describes how to properly connect the fieldbus to your DVC6200 digital valve controller․ For comprehensive technical details regarding planning and installation within a FOUNDATION Fieldbus system, refer to the official Foundation Technology Overview document․

This resource is readily available from both the Fieldbus Foundation and through detailed Fieldbus Installations guidance materials․ These supplementary resources provide in-depth information crucial for successful integration․ Always consult these documents alongside this manual to ensure a robust and reliable fieldbus connection, maximizing system performance and minimizing potential issues․

Configuration and Setup

Manual setup configures the controller to your application, adjusting actuator response, modes, alerts, ranges, travel cutoffs, and limits from default factory settings․

Manual Setup vs․ Default Factory Configuration

The DVC6200 offers both a default factory configuration and the flexibility of manual setup․ Utilizing Manual Setup empowers users to tailor the digital valve controller precisely to their specific application requirements․ This customization extends to a wide array of parameters, including fine-tuning actuator response characteristics for optimal performance․

Furthermore, manual configuration allows for the selection of various operating modes, the establishment of alert thresholds, and the precise definition of operational ranges․ Users can also implement travel cutoffs and limits, ensuring safe and controlled valve operation․ Table 5 and Table 6, detailed within the instruction manual, comprehensively list the default settings provided by the standard factory configuration, serving as a valuable reference point during the setup process․

Adjusting Actuator Response and Modes

The FIELDVUE DVC6200 allows precise control over actuator response, crucial for optimizing process dynamics․ Manual Setup provides the tools to adjust these parameters, influencing how quickly and smoothly the valve responds to control signals․ Different operating modes cater to diverse application needs, ranging from standard proportional control to more advanced functionalities․

Careful consideration of these settings is vital for achieving desired performance and stability․ Adjustments impact valve positioning accuracy and responsiveness․ The instruction manual details available modes and their implications, guiding users toward the optimal configuration for their specific process․ Proper tuning ensures efficient operation and minimizes process variability․

Setting Ranges, Travel Cutoffs, and Limits

Precise configuration of valve travel is essential for safe and efficient operation․ The DVC6200’s Manual Setup allows defining operational ranges, ensuring the valve operates within desired boundaries․ Travel cutoffs prevent over-travel, protecting the valve and associated equipment from damage․ Setting appropriate limits safeguards against unintended process upsets and maintains system integrity․

These parameters are application-specific and require careful consideration of process requirements․ The instruction manual provides guidance on determining suitable values, referencing the valid travel range on the magnet assembly․ Correctly defined ranges and limits optimize performance and enhance overall system reliability, preventing unwanted valve positions․

FOUNDATION Fieldbus Integration

For FOUNDATION Fieldbus details, consult the Foundation Technology Overview and Fieldbus Installations guidance documents, available from the Fieldbus Foundation․

Referencing Foundation Technology Overview

The Foundation Technology Overview serves as a crucial resource for understanding the intricacies of FOUNDATION Fieldbus, a key component in the DVC6200’s functionality․ This document, readily available from the Fieldbus Foundation, provides a comprehensive technical description of the protocol and its implementation․ It details planning considerations, ensuring a smooth and efficient installation process․

Specifically, it outlines the foundational principles governing communication, device profiles, and network architecture․ Referencing this overview is essential for anyone involved in the configuration, troubleshooting, or maintenance of DVC6200 controllers within a FOUNDATION Fieldbus environment, guaranteeing optimal performance and interoperability․

Fieldbus Installations Guidance

Successful Fieldbus installations with the DVC6200 require careful adherence to established guidelines․ Beyond the Foundation Technology Overview, specific Fieldbus Installations guidance is available to ensure robust and reliable network operation․ This guidance covers critical aspects like segment design, termination, and power considerations․

Proper grounding and shielding are paramount to minimize noise and interference, safeguarding data integrity․ Furthermore, it details best practices for cable selection and routing, optimizing signal transmission․ Following these recommendations will contribute to a stable and efficient Fieldbus network, maximizing the DVC6200’s performance and longevity․

Advanced Configuration Options

Configure alerts and utilize diagnostic features for optimal performance; Adjust actuator response, set modes, ranges, travel cutoffs, and limits as needed․

Alert Configuration and Management

The DVC6200 allows for comprehensive alert configuration, enabling proactive monitoring of valve controller performance․ Users can adjust various alert parameters to suit specific application requirements․ This includes setting thresholds for critical process variables and defining appropriate response actions when alerts are triggered․

Effective alert management is crucial for maintaining system reliability and preventing unexpected downtime․ The controller supports multiple alert types, allowing for granular control over notification preferences․ Proper configuration ensures operators receive timely and relevant information, facilitating swift corrective actions and optimizing overall process efficiency․ Detailed documentation within the instruction manual guides users through the alert setup process․

Understanding and Utilizing Diagnostic Features

The FIELDVUE DVC6200 incorporates robust diagnostic capabilities designed to simplify troubleshooting and enhance maintenance practices․ These features provide valuable insights into the controller’s operational status, identifying potential issues before they escalate into significant problems․ Diagnostic data includes detailed information on actuator performance, communication integrity, and internal component health․

Effectively utilizing these diagnostics requires a thorough understanding of the available data and its interpretation․ The instruction manual provides comprehensive guidance on accessing and analyzing diagnostic information, enabling technicians to quickly pinpoint the root cause of any detected anomalies․ This proactive approach minimizes downtime and optimizes valve controller performance;

Hazardous Area Approvals

The DVC6200 meets stringent hazardous area standards; review nameplate information and specific certifications detailed within this manual for compliance guidelines․

Nameplate Information and Compliance

The DVC6200 nameplate provides crucial information regarding area classifications, certifications, and operational limits․ Carefully examine the nameplate to ensure the controller is suitable for the intended hazardous environment․ Compliance with local and national regulations is paramount when installing and operating this device․

Verify that the nameplate markings align with the specific hazardous area requirements of your application․ This includes checking for appropriate explosion-proof, intrinsically safe, or dust-ignition-proof ratings․ Incorrect installation or operation can compromise safety and void certifications․ Always refer to the complete certification documentation for detailed specifications and limitations․

Specific Hazardous Area Certifications

The FIELDVUE DVC6200 series achieves various hazardous area certifications, dependent on the specific hardware (HW1, HW2, SIS) and configuration․ These certifications demonstrate compliance with globally recognized standards for safe operation in potentially explosive atmospheres․ Common certifications include ATEX, IECEx, and North American standards (CSA, UL)․

Detailed certification information, including permitted temperature ranges, entity parameters, and installation instructions, is available in separate certification documentation accompanying the product․ Always consult these documents to ensure proper installation and operation within the specified hazardous area․ Failure to adhere to certification requirements can invalidate approvals and create safety risks․

Troubleshooting Common Issues

Addressing communication errors and actuator performance problems are key troubleshooting areas; proper alignment and fieldbus connections are vital for reliable operation․

Identifying and Resolving Communication Errors

Effective troubleshooting of communication issues with the DVC6200 requires a systematic approach․ Begin by verifying the fieldbus connection, ensuring proper termination and wiring according to the manual․ Check for physical layer problems, such as cable damage or loose connections․ Utilize diagnostic features within the controller to pinpoint error sources – these can reveal signal quality issues or bus contention․

Confirm compatibility between the DVC6200 and the host system, and review configuration settings for correct addressing and communication parameters․ If errors persist, consult the FOUNDATION Fieldbus documentation for detailed guidance on network diagnostics and troubleshooting procedures․ Remember to document all steps taken during the investigation․

Addressing Actuator Performance Problems

When encountering actuator issues with the DVC6200, begin by verifying proper mechanical linkage and alignment, referencing the mounting considerations in the instruction manual․ Check for obstructions or binding within the actuator assembly․ Utilize the controller’s diagnostic features to monitor actuator position and response time, identifying any deviations from expected behavior․

Adjust actuator response and modes as needed, ensuring settings align with the application requirements․ Confirm correct range and travel cutoff configurations․ If problems persist, inspect the valve itself for internal issues․ A thorough review of the valve and controller documentation is crucial for effective resolution․

Maintenance and Calibration

Regular maintenance schedules and calibration procedures are outlined to ensure optimal DVC6200 performance and reliability, extending its operational lifespan effectively․

Recommended Maintenance Schedules

To maintain optimal performance, a proactive maintenance approach is crucial for the DVC6200․ Routine visual inspections should occur monthly, checking for physical damage, loose connections, and environmental ingress․ Every six months, verify the actuator’s mechanical operation and confirm proper travel range alignment․

Annual calibration is recommended, particularly in critical applications, to ensure accuracy and responsiveness․ Detailed calibration procedures are outlined in the full instruction manual․ Consider more frequent checks in harsh environments or demanding processes․ Document all maintenance activities for traceability and performance tracking․ Following these schedules maximizes the DVC6200’s lifespan and minimizes unexpected downtime․

Calibration Procedures and Best Practices

Accurate calibration is vital for reliable DVC6200 operation․ Begin by ensuring a stable process and appropriate calibration tools․ Utilize the manual setup features to define accurate ranges and travel cutoffs․ Carefully align the magnet assembly, referencing the index mark on the pole pieces for precise positioning․

Document initial readings before adjustments․ Implement a step-by-step calibration process, verifying each point against known standards․ Regularly check for linearity and hysteresis․ Retain calibration records for future reference and troubleshooting․ Following these best practices ensures consistent and dependable valve control․

Technical Specifications

The DVC6200’s specifications include detailed physical dimensions, weight, and electrical/environmental parameters crucial for proper installation and application suitability․

DVC6200 Physical Dimensions and Weight

Understanding the DVC6200’s physical characteristics is vital for successful integration into existing systems․ Precise dimensions ensure compatibility with valve assemblies and mounting locations, preventing installation challenges․ The controller’s weight is a critical factor for structural support considerations, particularly in demanding industrial environments․

Detailed drawings and specifications are available within the full instruction manual (D103412X012), outlining exact measurements for height, width, and depth․ These specifications accommodate various configurations, including standard, SIS, and different hardware revisions (HW1, HW2)․ Accurate weight data facilitates safe handling and transportation, minimizing potential risks during deployment and maintenance procedures․

Electrical and Environmental Specifications

The DVC6200 operates within defined electrical parameters, crucial for safe and reliable performance․ Input voltage ranges, power consumption, and output signal characteristics are detailed in the instruction manual, ensuring compatibility with plant power systems and control networks․ Environmental resilience is paramount; the controller withstands specified temperature ranges, humidity levels, and vibration frequencies․

Compliance with relevant standards, including hazardous area certifications, is clearly documented․ Understanding these specifications prevents operational failures and maintains system integrity․ Proper grounding and wiring practices, as outlined in the manual, are essential for electromagnetic compatibility and personnel safety․